Copyright © 1996 - 2015 Dr. Alan J. Pierce

You are welcome to print material from this website for use in your classroom.

Product Review of the Da Vinci Line of 3D Printers

The Da Vinci 1.0 ($499.00), Da Vinci 2.0 ($649.99) and Da Vinci 1.0 AiO ($799.99) are all built using the same housing, heated building table, internal carriages, drive motors, drive belts, and the same drive screw to incrementally lower the build table. All three models have the same outside dimensions which is 18.4 X 20 X 22 inches and the same ability to build a 7.8 X 7.8 X 7.8 inch object. They all have the same type extruder that has a nozzle opening of 0.4 mm. All three machines use the same proprietary filament cartridge which holds 600 g of 1.75 mm thick filament. The spool inside these cartridges contains 240 m (787 feet) of filament. The “free” starter cartridge that comes with the machine is only half full and a chip at the bottom of these cartridges reads the type of plastic you are running and also how much plastic is left in the box.

They all use the same building software (XYZware). So when it comes to building projects all three machines have the same strengths and also the same weaknesses. These Da Vinci 3D printers let you select your layer height from a tiny 100 microns to a maximum of 400 microns. The narrated video that I created on the software visually shows you all that you can do with the software and the video also discusses its limitations:

http://www.youtube.com/watch?v=5I4Xzpo9ng4.

What Makes Each of these Machines Unique!

The Da Vinci 1.0 is XYZ printing’s first commercial 3D printer. It was introduced at CES 2014 and it won an Editor’s Choice Award at the show. On this machine you can build objects in a single color. To build objects in a different color you would have to switch filament cartridges. Switching is time consuming and you can’t switch cartridges in the middle of a project.

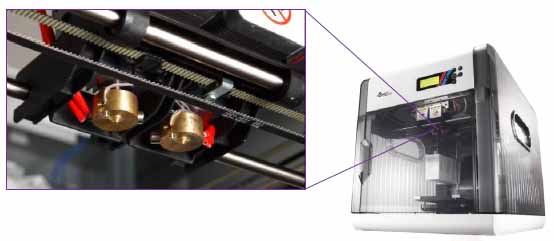

The Da Vinci 2.0 has two extruders. This allows you to run two different color filaments at the same time. You can’t switch extruders (colors) in the middle of a layer. You can alternate layer colors as much as you want but never produce a two color layer. Before you send your project to the printer you determine which layers will be built in color A and which will be built in color B; using the XYZware software. You can see the two extruder layout in photo 3.

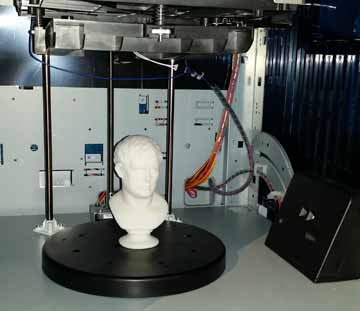

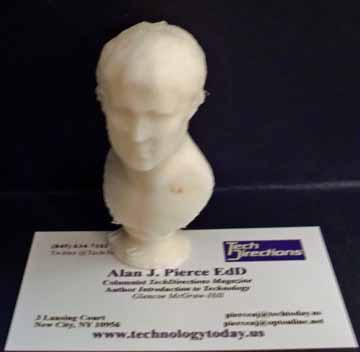

The Da Vinci 1.0 AiO has one extruder. What makes it special is it has a built in laser 3D scanner that can scan the top and all around objects 15 cm x 15 cm x 15 cm (5.9 inches) at a 0.25 mm resolution. See photo 4. At CES 2015 an XYZ Printing representative copied an STL file of an object that they just fully scanned onto my memory stick. I used this file to build a replica of the bust of Marcus Vipsanius Agrippa. See photo 5.

The narrated video that I created gives you a tour of the internal similarities and differences between these 3D printers. It also discusses their strengths and limitations. It is located at: http://www.youtube.com/watch?v=I4i0w89Vp6o&feature=youtu.be.

For a fun machine to make craft projects at home or to teach the basic concepts of 3D printing in school, these Fused Filament Fabrication 3D printers, regardless of the manufacturer, do a great job. The biggest advantage that the Da Vinci line of 3D printers has over the competition is the quality of the construction and their price. To match these machines’ features and quality you can expect to spend two to three times as much money buying a machine from a different manufacturer. The 3rd video is a time lapse photography build of an Aphrodite statue. The layer height was set at 400 microns to reduce filming time. It was built without support so you could see the project without it being totally enshrouded in plastic. The arms and knees definitely needed support. The video is located at:

http://www.youtube.com/watch?v=buH7ProhzvA&feature=youtu.be.

XYZ Printing is an extremely well funded subsidiary of the world’s largest original equipment manufacturer of printers and other electronic products. The parent company has manufactured products for Sony, Microsoft, HP, Epson, and many other brand names you are extremely familiar with.

Reasons to Drool

To match the quality and features of these machines you would need to spend two to three times as much money buying someone else’s product. These machines come fully assembled (you do need to load the filament cartridge) and they are extremely easy to setup and use. The table is pre-calibrated at the factory and if calibration becomes necessary the LCD screen helps you make the adjustments. If you download an STL project from the Internet you can literally start building it within a half hour of unpacking the machine. The build platform is heated and provides a large enough surface to build large objects.

Not So Cool

The filament comes in proprietary cartridges and an electronic chip at the bottom of the cartridge prevents you from refilling them. The XYZware software gives you very little control over the building process. Watch the video to see what you can do. To replace this software on your computer and on the machine you would have to void the warranty. The glass build plate is not removable and the heating element is actually printed right onto the glass. If you break the glass removing a project you will also have to replace the heating element.

Photo 1

DaVinci 1.0, 2.0, and 1.0 AiO

By Alan J. Pierce EdD

pierceaj@techtoday.us

Photo 3

Da Vinci 2.0

has 2 Extruders

Photo 4

DaVinci 1.0 AiO

Built-in Scanner

Photo 5

Built using STL file created on the 1.0 AiO

Providing Classroom Resources on New & Emerging Technologies

TechnologyToday.us